Yakaputirwa Nemakomba PTH Maitiro muPCB fekitori---Electroless Chemical Copper Plating

Zvinenge zvesePCBs ine mativi maviri kana akawanda-layers anoshandisa akapfava nemaburi (PTH) kubatanidza ma conductor pakati pemukati me layer kana kunze ma layer, kana kubata zvinhu zvinotungamira waya.Kuti uite izvozvo, nzira dzakanaka dzakabatana dzinodiwa kuti ikozvino iyerere nemakomba.Nekudaro, kusati kwaitwa plating process, kuburikidza nemakomba haisi-conductive nekuda kweakadhindwa edunhu mabhodhi anoumbwa neasina-conductive composite substrate zvinhu (epoxy-girazi, phenolic-bepa, polyester-girazi, nezvimwewo).Kugadzira kuita zvakanaka kunyangwe nzira dzegomba, angangoita 25 microns (1 mil kana 0.001 mukati) yemhangura kana yakawanda yakatsanangurwa nedhizaini bhodhi mugadziri anodiwa kuti aiswe electrolytically pamadziro emakomba kugadzira yakakwana kubatana.

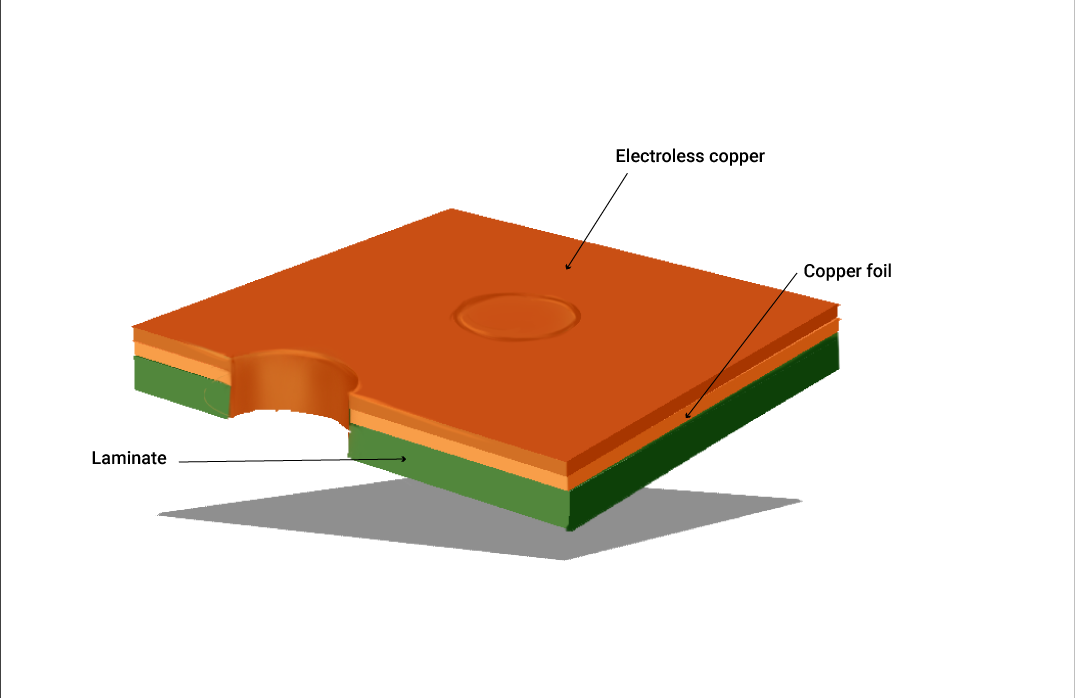

Pamberi pe electrolytical copper plating, nhanho yekutanga ndeyekemikari yemhangura yendarira, inonziwo electroless copper deposition, kuwana yekutanga conductive layer pamadziro emaburi eakadhindwa wiring board.Iyo autocatalytic oxidation-reduction reaction inoitika pamusoro peiyo isiri-kuitisa substrate yemuburi.Pamadziro jasi rakatetepa kwazvo remhangura rinenge 1-3 micrometer ukobvu inoiswa mumakemikari.Chinangwa chayo ndechekuita kuti gomba rive rakakwana kuti ribvumire kuwedzera kuvakwa nemhangura yakaiswa electrolytically kune ukobvu hunotsanangurwa newaya bhodhi mugadziri.Kunze kwemhangura, tinogona kushandisa palladium, graphite, polymer, nezvimwewo semakondakita.Asi mhangura ndiyo yakanakisa sarudzo yemugadziri wemagetsi panguva dzakajairika.

Sezvo IPC-2221A tafura 4.2 ichitaura kuti hushoma hwemhangura hukobvu huri kuiswa ne electroless copper plating nzira pamadziro ePTH yeavhareji yekuiswa kwemhangura ndeye 0.79 mil yekirasi Ⅰ uye Kirasi Ⅱ uye 0.98 milclassⅢ.

Iyo kemikari yemhangura yekuisa mutsara inodzorwa zvizere nekombuta uye mapaneru anotakurwa kuburikidza nenhevedzano yekemikari uye yekugezesa yekugezesa neyepamusoro crane.Pakutanga, iyo pcb mapaneru anofanorapwa, achibvisa zvese zvakasara kubva pakuchera uye achipa yakanakisa roughness uye electro positiveness yekemikari deposition yemhangura.Nhanho yakakosha ndeye permanganate desmear process yemakomba.Munguva yekurapa, mutete wakatsetseka we epoxy resin unodzikwa kubva kumucheto wemukati wemukati uye madziro emakomba, kuve nechokwadi chekunamatira.Ipapo madziro ese egomba anonyudzwa mumabhati anoshanda kuti awane mbeu ine micro-particles ye palladium mumabhati anoshanda.Iyo yekugezesa inochengetedzwa pasi peyakajairika mhepo kubvongodza uye mapaneru anogara achifamba nemubhavhu kuti abvise mhepo inoputika inogona kunge yakaita mukati memakomba.Mutsetse mutete wemhangura wakaiswa pamusoro pese pese peni uye akaboorwa maburi mushure mekugeza palladium.Electroless plating nekushandiswa kwepalladium inopa kunamatira kwakasimba kwemhangura yekuputira kune fiberglass.Pakupera kwekuongorora kunoitwa kutarisa porosity uye ukobvu hwejasi remhangura.

Nhanho imwe neimwe yakakosha kuhurongwa hwese.Chero kusabatwa zvakanaka mukuita kunogona kukonzera kuti batch yese yemabhodhi ePCB iparare.Uye yekupedzisira mhando pcb nhema zvakanyanya mumatanho iwayo ataurwa pano.

Iye zvino, nemakomba ekuitisa, kubatanidza magetsi pakati pezvikamu zvemukati uye kunze kwezvikamu zvakagadzirirwa mabhodhi edunhu.Danho rinotevera nderekukura mhangura mumakomba iwayo uye kumusoro nepasi pemabhodhi ewaya kusvika kune ukobvu chaihwo - copper electroplating.

Yakazara otomatiki kemikari electroless mhangura yekuisa mitsetse muPCB ShinTech ine Kucheka kumucheto PTH Technology.

Nguva yekutumira: Jul-18-2022