Zvakatumirwa: Kukadzi 15, 2022

Categories:Blogs

Tags:pcb, pcbs, pcba, pcb ungano, smt, stencil

Chii chinonzi PCB Stencil?

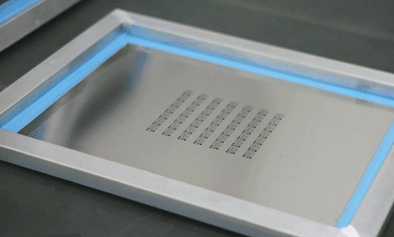

PCB Stencil, inozivikanwawo seSimbi mesh, ipepa re stai

isina simbi ine laser yekucheka mavhuriro anoshandiswa kuendesa huwandu hwakaringana hwesolder paste kune chaiyo yakatarwa chinzvimbo paPCB isina chinhu yekuiswa pamusoro pegomo rekuisa.Iyo stencil inoumbwa ne stencil furemu, waya mesh uye simbi sheet.Kune maburi akawanda mu stencil, uye nzvimbo dzemaburi aya dzinoenderana nenzvimbo dzinoda kudhindwa paPCB.Basa guru re stencil nderokunyatsoisa chiyero chakanaka che solder paste pamapadhi kuitira kuti solder joint pakati pedhi uye chikamu ive yakakwana maererano nemagetsi ekubatanidza uye simba remagetsi.

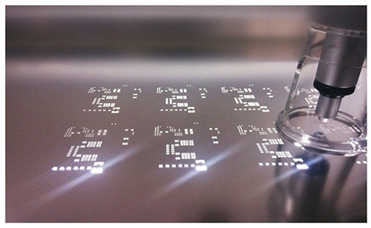

Paunenge uchishandiswa, isa PCB pasi pe stencil, Kamwe iyo

stencil yakanyatsorongedzwa pamusoro pebhodhi, solder paste inoshandiswa pamusoro pekuzarura.

Ipapo iyo solder paste inodonhedzwa kuPCB pamusoro kuburikidza nemaburi madiki panzvimbo yakatarwa pane stencil.Kana iyo foil yesimbi inoparadzaniswa kubva pabhodhi, solder paste icharamba iri pamusoro pebhodhi redunhu, yakagadzirira kuiswa kwepamusoro-soro michina (SMDs).Iyo shoma solder paste yakavharwa pane stencil, iyo yakawanda inoiswa paPCB.Iyi nzira inogona kudzokororwa nemazvo, saka inoita kuti chirongwa cheSMT chikurumidze uye chiwedzere kuenderana uye ive nechokwadi chekuti mutengo-unoshanda wePCB Assembly.

Chii chinonzi PCB Stencil yakagadzirwa?

A SMT stencil inonyanya kugadzirwa ne stencil furemu, mesh uye

Stainless-simbi pepa, uye glue.Inowanzo shandiswa stencil furemu ndiyo inonamira kune waya mesh neglue, iri nyore kuwana yunifomu yesimbi tension, iyo inowanzoita 35 ~ 48N / cm2.Mesh ndeyekugadzirisa simbi pepa uye furemu.Kune marudzi maviri emambure, Stainless simbi waya mesh uye polymer polyester mesh.Iyo yekutanga inogona kupa yakagadzikana uye yakakwana tension asi iri nyore kukanganisa uye kupera.Iyo yakazotevera zvakadaro inogona kugara kwenguva yakareba ichienzaniswa nesimbi isina tsvina waya mesh.Kazhinji inogamuchirwa stencil sheet i301 kana 304 Stainless simbi sheet izvo zviripachena zvinovandudza kuita kweiyo stencil kuburikidza neayo emhando yemakina.

Kugadzira Nzira yeStencil

Kune marudzi manomwe emastencils uye nzira nhatu dzekugadzira stencils: makemikari etching, laser yekucheka uye electroforming.Kazhinji inoshandiswa inonzi laser simbi stencil.Las

er stencil ndiyo inonyanya kushandiswa muSMT indasitiri, inoratidzirwa ndeiyi:

Iyo data data inoshandiswa zvakananga kuderedza kukanganisa kwekugadzira;

Iyo yekuvhura chinzvimbo kurongeka kweSMT stencil yakakwira zvakanyanya: iyo yese process kukanganisa ndeye ≤± 4 μ m;

Kuvhurwa kweSMT stencil ine geometry, inova conduci

ve kudhinda uye kuumbwa kwe solder paste.

Laser yekucheka maitiro kuyerera: firimu kugadzira PCB, kutora marongero, data faira, kugadzirisa data, laser kucheka, kugaya.Iyo nzira ine yakakwira dhizaini kurongeka uye kushoma pesvedzero yechinangwa zvinhu;Kuvhura kweTrapezoidal kunobatsira kudhiza, inogona kushandiswa kuchekwa chaiko, mutengo wakachipa.

General zvinodiwa uye misimboti PCB Stencil

1. Kuti uwane kudhindwa kwakakwana kwe solder paste paPCB pads, iyo chaiyo nzvimbo uye yakatarwa ichave nechokwadi chekuvhura kwepamusoro, uye kuvhura kuchave kwakanyatso kuenderana neyakatsanangurwa nzira yekuvhura inotaurwa kune fiducial mamaki.

2. Kuti udzivise kukanganiswa kwe solder senge bridging uye solder bead, iyo yakazvimirira yekuvhura ichagadzira diki zvishoma pane PCB padhi saizi.hupamhi hwese hahufaniri kudarika 2mm.Nzvimbo yePCB pad inofanira kugara yakakura kudarika zvikamu zviviri kubva muzvitatu zvemukati wemadziro ekuvhara kwe stencil.

3. Pakutambanudza mesh, nyatsoidzora, uye pa

y kunyanya kutarisisa kune yekuvhura renji, iyo inofanirwa kunge yakatwasuka uye yakatarisana.

4. Nenzvimbo yekudhinda seyokumusoro, kuvhurwa kwepasi kwe mesh kuchave 0.01mm kana 0.02mm yakafara kupfuura yekuvhura kwepamusoro, ndiko kuti, kuvhurwa kuchave kwakatenderedzwa conical kufambisa kuburitswa kwe solder paste uye kuderedza kucheneswa. nguva dze stencil.

5. The mesh wall inofanira kuva yakatsetseka.Kunyanya kuQFP neCSP ine spacing isingasviki 0.5mm, mutengesi anodiwa kuti aite electropolishing panguva yekugadzira.

6. Kazhinji, iyo stencil yekuvhura tsanangudzo uye chimiro cheSMT zvikamu zvinopindirana nepedhi, uye chiyero chekuvhura ndeye 1: 1.

7. Kunyatsokora kwepepa re stencil kunovimbisa kusunungurwa

yehuwandu hunodiwa hwe solder paste kuburikidza nekuvhura.Extra solder deposition inogona kukonzera solder bridging nepo kushoma solder kukonzeresa kukonzeresa majoini ekutengesa.

Nzira yekugadzira PCB Stencil?

1. 0805 pasuru inokurudzirwa kucheka mapadhi maviri ekuvhura ne 1.0mm, uyezve kuita concave denderedzwa B = 2 / 5Y;A = 0.25mm kana a = 2/5 * l anti tin bead.

2. Chip 1206 uye pamusoro: mushure mokunge mapepa maviri aendeswa kunze ne 0.1mm maererano, ita denderedzwa remukati remukati B = 2 / 5Y;A = 2 / 5 * l anti tin bead kurapwa.

3. For PCB pamwe BGA, kuvhura reshiyo stencil nebhora spacing kupfuura 1.0mm ndiye 1: 1, uye kuvhura reshiyo stencil nebhora spacing isingasviki 0.5mm ndiyo 1:0.95.

4. Kune ese QFP neSOP ine 0.5mm pitch, rati yekuvhura

o muhupamhi hwehupamhi hwakazara i1: 0.8.

5. Kuvhura reshiyo mukureba nhungamiro ndeye 1: 1.1, ine 0.4mm pitch QFP, kuvhura muhupamhi hwese kutungamira ndeye 1: 0.8, kuvhura muhurefu kutungamira ndeye 1: 1.1, uye yekunze inotenderera tsoka.Chamfer radius r = 0.12mm.Iyo yakazara yekuvhura upamhi hweSOP element ine 0.65mm pitch inoderedzwa negumi%.

6. Kana PLCC32 uye PLCC44 yezvigadzirwa zvakajairwa zvakapwanyika, iyo yakazara hupamhi kutungamira i1: 1 uye kureba kutungamira iri 1:1.1.

7. Kune general SOT packaged devices, the opening reshiyo

yepedhi hombe inopera ndeye 1: 1.1, iyo yakazara hupamhi kutungamira kwediki padhi yekupedzisira i1: 1, uye kureba kutungamira i1: 1.

SeiKushandisa PCB Stencil?

1. Bata nokungwarira.

2. Stencil ichacheneswa isati yashandiswa.

3. Solder paste kana red glue ichashandiswa zvakafanana.

4. Gadzirisa kudhindwa kwekudhinda kune zvakanakisisa.

5. Kushandisa pasteboard kudhinda.

6. Mushure mekurohwa kwekutsvaira, zvakanakisisa kumira kwe 2 ~ 3 seconds isati yadhimoulding, uye kuisa kukurumidza kwekugadzirisa kwete kunyanya kukurumidza.

7. Stencil ichacheneswa nenguva, yakachengetwa zvakanaka mushure mekushandiswa.

Stencil Manufacture Service yePCB ShinTech

PCB ShinTech inopa Laser Stainless simbi stencils kugadzira masevhisi.Isu tinogadzira stencils ane ukobvu hwe100 μm, 120 μm, 130µm, 150 μm, 180 μm, 200 μm, 250 μm uye 300 μm.Iyo data faira inodiwa kugadzira iyo laser stencil inofanirwa kunge iine SMT solder paste layer, fiducial mark data, PCB outline layer uye character layer, kuti titarise kumberi nekumashure mativi edata, chikamu chechikamu, nezvimwe.

Kana iwe uchida quote ndapota tumira mafaera ako uye kubvunza kunesales@pcbshintech.com.

Nguva yekutumira: Jun-10-2022